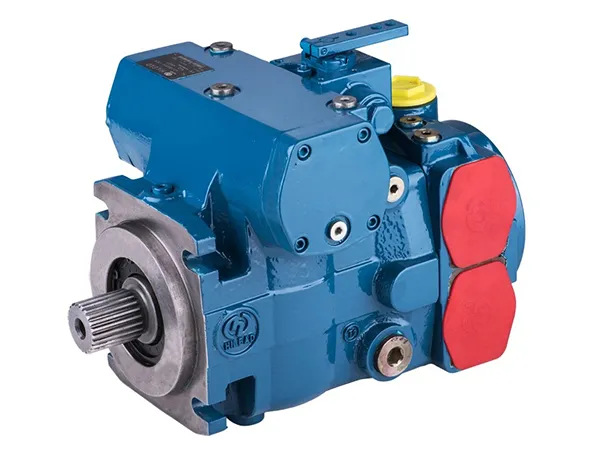

- Displacement: 10-200 cm³/rev

- Nominal pressure: 400 bar

- Max. allowable pressure: 450 bar

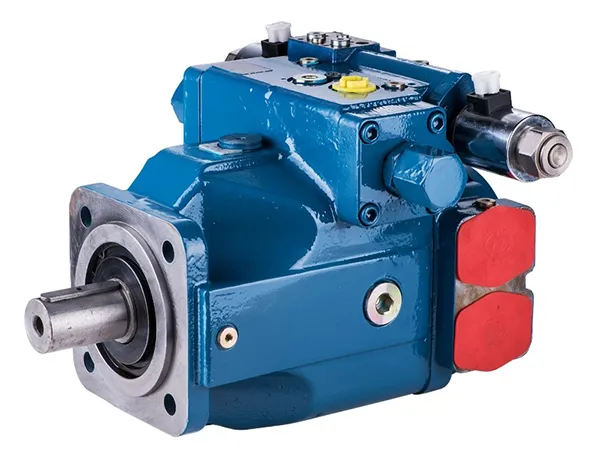

- Displacement: 71/90 cm³/rev

- Nominal pressure: 400 bar

- Max. allowable pressure: 450 bar

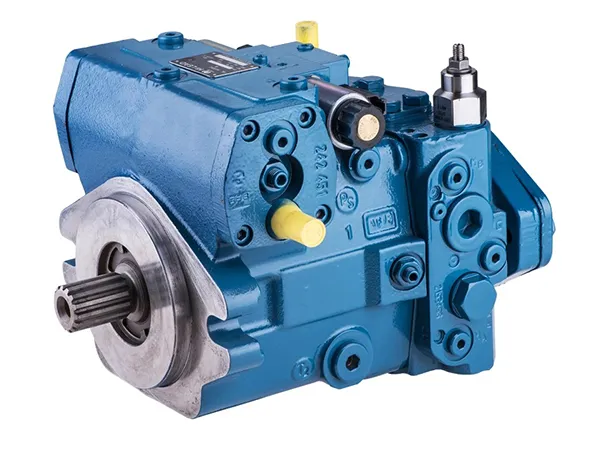

- Displacement: 40-500 cm³/rev

- Nominal pressure: 350 bar

- Max. allowable pressure: 400 bar

- Displacement: 40-180 cm³/rev

- Nominal pressure: 400 bar

- Max. allowable pressure: 450 bar

- Displacement: 40-500 cm³/rev

- Nominal pressure: 350 bar

- Max. allowable pressure: 400 bar

- Displacement: 40-500 cm³/rev

- Nominal pressure: 350 bar

- Max. allowable pressure: 400 bar

- Displacement: 20-500 cm³/rev

- Nominal pressure: 350 bar

- Max. allowable pressure: 400 bar

- Displacement: 140 cm³/rev

- Nominal pressure: 350 bar

- Max. allowable pressure: 400 bar

- Displacement: 10-100 cm³/rev

- Nominal pressure: 250 bar

- Max. allowable pressure: 315 bar

- Displacement: 45 cm³/rev

- Nominal pressure: 350 bar

- Max. allowable pressure: 400 bar

- Displacement: 18-140 cm³/rev

- Nominal pressure: 280 bar

- Max. allowable pressure: 350 bar

- Displacement: 74-260 cm³/rev

- Nominal pressure: 350 bar

- Max. allowable pressure: 400 bar

- Maximum Efficiency Achieve 94%+ efficiency, reducing energy loss and operating costs.

- Built to Last Our pumps resist contamination, feature imported sealing components, and undergo rigorous reliability testing.

- Precision Control & Quick Response Get highly responsive operation with proportional pump response times under 200ms.

- High-Pressure Performance Handle peak pressures up to 450 bar.

- Heavy-Duty Build Developed with high-strength, wear-resistant materials to withstand the toughest conditions.

- Compact & Space-Saving Engineered for maximum efficiency in minimal space.

- Versatile Torque & Displacement Options Ensuring compatibility with your specific application.

What is the difference between variable displacement axial piston pumps and fixed displacement axial piston pumps?

Variable displacement axial piston pumps allow for dynamic adjustment of displacement according to the hydraulic system’s needs. These pumps are ideal for applications where the load varies and flexible flow adjustment is required, such as hydraulic drive systems, excavators, and injection molding machines. On the other hand, fixed displacement axial piston pumps cannot adjust displacement based on system needs. They are best suited for systems that require a constant flow and experience minimal load changes, like simpler hydraulic control systems.

How do I choose the right axial piston pump?

Selecting the right axial piston pump involves considering the following factors:

- Operating pressure: Choose the appropriate pressure rating based on your system’s requirements.

- Flow requirements: Match the pump model with the hydraulic system's flow needs.

- Efficiency and durability: Opt for pumps that offer high efficiency and durability to reduce failure rates and maintenance costs.

- Pump type: Consider whether a fixed displacement or variable displacement axial piston pump suits your application.

- Control method: Select the appropriate control method based on operational needs.

What advantages do axial piston pumps offer in construction machinery?

Axial piston pumps provide several advantages in construction machinery, including:

- High pressure capability: They are well-suited for high-pressure applications, providing powerful hydraulic performance.

- Durability & reliability: These pumps are designed for heavy-duty use, maintaining long service life in harsh working environments.

- Adjustable displacement: Variable displacement pumps automatically adjust the flow to match demand, enhancing efficiency.

- Compact design: Their compact size and lightweight build make them ideal for space-constrained environments.

- Efficient control options: Closed-loop pumps with electric proportional control, hydraulic control, and mechanical servo control improve efficiency, precision, and energy savings.

How do you handle high-temperature operation in axial piston pumps for steelmaking and metallurgy?

To address high-temperature challenges in metallurgy, we recommend implementing an optimized cooling system to maintain the pump temperature and prevent overheating. Regular maintenance of the cooling system is essential to ensure optimal performance. Additionally, using hydraulic fluids specifically designed for high-temperature environments is crucial, as they help maintain pump efficiency and prolong its lifespan by preventing excessive fluid temperatures from impacting the pump's performance.

What are the key features of axial piston pumps?

Axial piston pumps have several standout features, including:

- High operating pressure: These pumps are capable of withstanding pressures in the range of 20-40 MPa.

- High efficiency: They offer both volumetric and mechanical efficiency, making them ideal for energy-sensitive applications.

- Versatile variable displacement: The pumps can be configured for multiple applications, providing flexibility.

- Compact & lightweight: Designed for use in space-limited environments, they offer a smaller footprint without compromising performance.

Ningbo Hilead Hydraulic Co., Ltd. is a professional manufacturer specializing in the design, development, production, and sales of hydraulic systems, pumps, motors, and presses. Our products are widely used in industries such as construction machinery, metallurgy, machine tools, environmental protection, marine engineering, petroleum and petrochemicals, agriculture, mining, construction, water conservancy, and aerospace.

Established in 1963, our company spans 25,000 square meters, including 16,000 square meters of factory space and a 10,000-square-meter office building.

Read More- Founded in 1963 with decades of hydraulic expertise

- Over 10,000 piston pumps produced

- Equipped with 12 advanced testing platforms

- All products are 100% tested before leaving the factory