From the very beginning, Hilead has focused on the research and production of hydraulic pumps and motors. Thanks to exceptional product performance and reliable quality, we quickly gained recognition in the industry and established long-term partnerships with leading hydraulic press manufacturers, becoming a key supplier of core hydraulic components.

Our in-depth collaboration with hydraulic press manufacturers has given us valuable insights into technical architecture, performance requirements, and market demands. To expand our business and meet your growing needs, Hilead has entered the field of hydraulic press manufacturing. We leverage the technical strengths and industry experience gained from hydraulic pump and motor development, integrating this expertise into every stage of hydraulic press design and production, offering complete and advanced hydraulic system solutions.

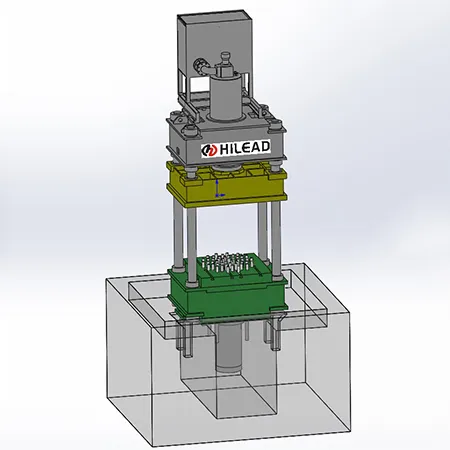

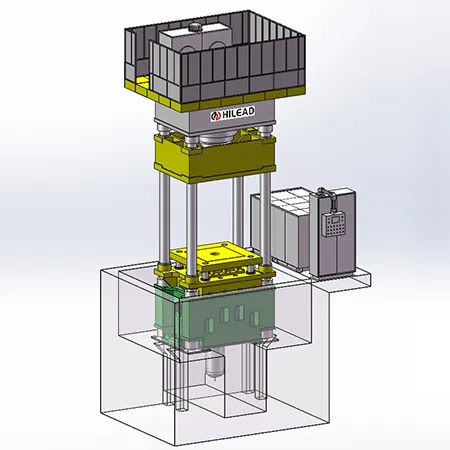

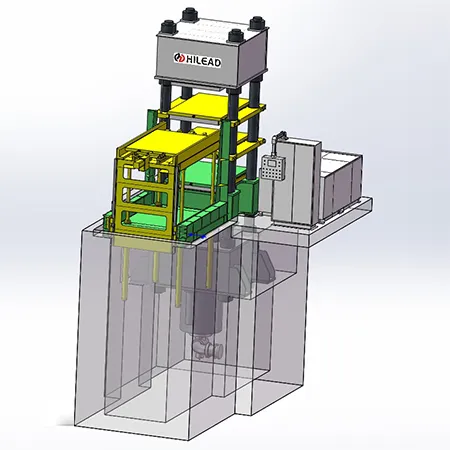

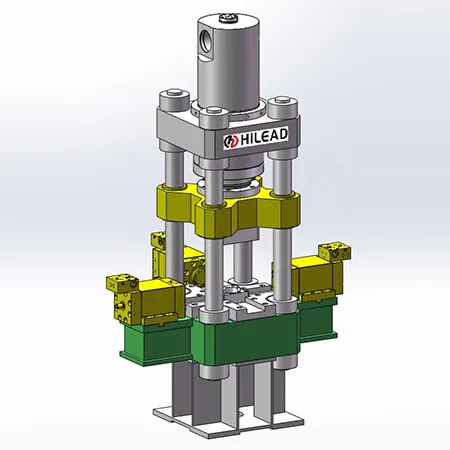

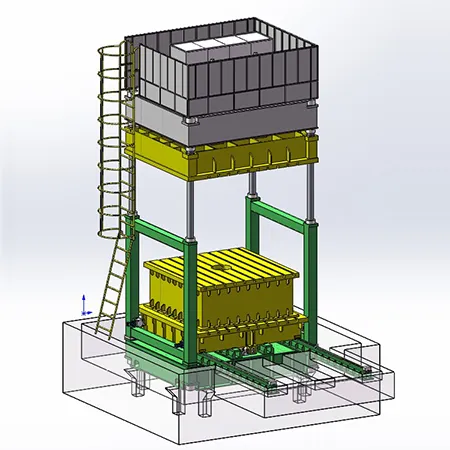

Hilead hydraulic presses can be tailored specifically for you. Based on your production process requirements, we provide customized solutions covering pressing capacity, mold opening force, daylight opening height, and slide stroke, ensuring each design meets your operational goals and supports greater efficiency and precision in your manufacturing.

At Hilead, every composite hydraulic press is custom-designed to match your specific needs. Beyond molding SMC, BMC, GMT, LET-D, and other thermoset, thermoplastic, and carbon fiber composites, we also offer complete automated system solutions for advanced composite material applications. Our presses are widely used in industries such as marine, automotive, construction, petrochemicals, energy, building materials, power and electrical equipment, telecommunications, rail transit, aerospace, and aviation.

Learn More

How do I determine the required tonnage for a hydraulic press?

Determining the required tonnage for a hydraulic press depends on several factors, including the processing method, material properties, workpiece size, and equipment parameters. Here are the key considerations:

-

Processing method:

- Molding: Consider the chemical properties of the material and the curing force needed for forming.

- Stamping: Involves shear forces, so cutting forces need to be calculated.

- Bending: Requires calculating the bending force while considering material rebound.

- Stretching/forming: Involves calculating stretching force and blank holder force.

- Extrusion/forge: Consider material flow resistance.

- Add a safety margin: The calculated tonnage should include an additional 20%-30% to accommodate material variations, mold wear, and other uncertainties.

- Consult with experts: Refer to hydraulic press manufacturer’s tonnage recommendations, and consult engineers for complex processes or specialized materials (like composites, high-strength steels, or titanium alloys).

- Final decision principle:

- Opt for larger tonnage rather than smaller to avoid overloading the press, which extends the machine’s lifespan.

- Match the tonnage to the process requirements, balancing speed, accuracy, and stability.

- Consider the economics by selecting a cost-effective model that meets your needs.

What safety features do hydraulic presses include?

Hydraulic presses are equipped with multiple safety features to ensure operator protection and machine safety such as:

- Emergency stop button

- Safety guarding devices

- Photoelectric safety

- Two-hand start control

- Hydraulic anti-drop support mechanisms

- Hydraulic anti-drop signal feedback

- Mechanical safety locking pins

- Self-Diagnosis system

These features help prevent accidents and ensure safe operation in various environments.

How do hydraulic presses improve efficiency in automotive manufacturing?

Hydraulic presses are widely used in the production of automotive parts, where they perform processes, such as stamping, stretching, flanging, and shaping. By integrating with automatic robotic arms and grippers, hydraulic presses speed up the loading and unloading of workpieces, reducing manual intervention and enhancing equipment utilization. This automation reduces cycle times and increases productivity, making manufacturing processes faster and more efficient.

What are the advantages of using hydraulic presses in the metallurgy and steelmaking industries?

Hydraulic presses offer several advantages in metallurgy and steelmaking such as:

- High pressure and large tonnage: Hydraulic presses can generate pressure ranging from hundreds of tons to tens of thousands of tons, making them suitable for processing high-strength metallic materials.

- Wide processing range: Capable of performing forging, extrusion, correction, shearing, and other metalworking processes with high adaptability.

- Precision and repeatability: Advanced CNC systems provide ±0.01mm precision control, ensuring consistent product quality.

- Automation integration: Hydraulic presses can be integrated with robots, automatic feeding systems, and rapid mold change systems, enabling fully automated operations.

Our dedicated hydraulic press manufacturing facility is located in Dongwu Town, covering an area of over 45 acres. This advanced site is responsible for the machining, production, assembly, and testing of hydraulic presses and hydraulic systems.

The assembly workshop boasts a height of 30 meters and is equipped with two double-beam cranes with a maximum lifting capacity of 100 tons. The facility features state-of-the-art equipment, including large-scale boring and milling machines capable of handling workpieces measuring up to 10 meters by 6 meters.

At this facility, we produce a full range of hydraulic presses with capacities from 200T to 10,000T, ensuring we meet diverse customer demands with precision, quality, and reliability.

Contact us today to explore the solutions that match your specific requirements.

- Covers over 30,000 square meters

- Equipped with high-end machining tools, including large-scale boring and milling machines up to 10m × 6m

- Capable of producing hydraulic presses ranging from 200T to 10,000T