Hydraulic Composite Press

At Hilead, every composite hydraulic press is custom-designed to match your specific needs. Beyond molding SMC, BMC, GMT, LET-D, and other thermoset, thermoplastic, and carbon fiber composites, we also offer complete automated system solutions for advanced composite material applications. Our presses are widely used in industries such as marine, automotive, construction, petrochemicals, energy, building materials, power and electrical equipment, telecommunications, rail transit, aerospace, and aviation.

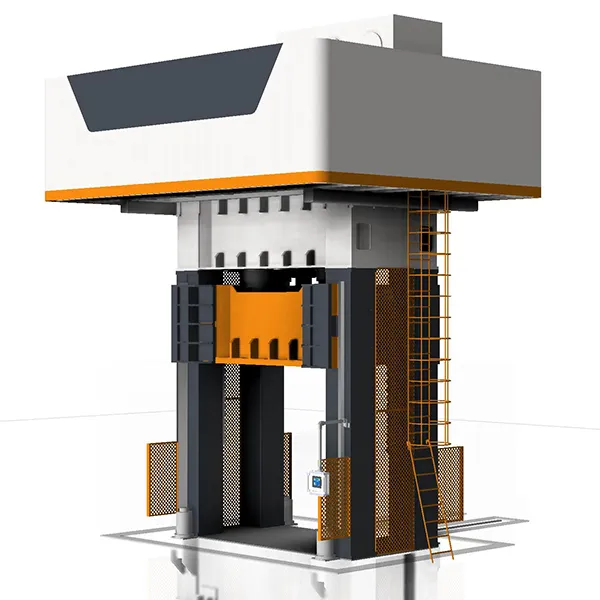

- 4-Post Hydraulic Press

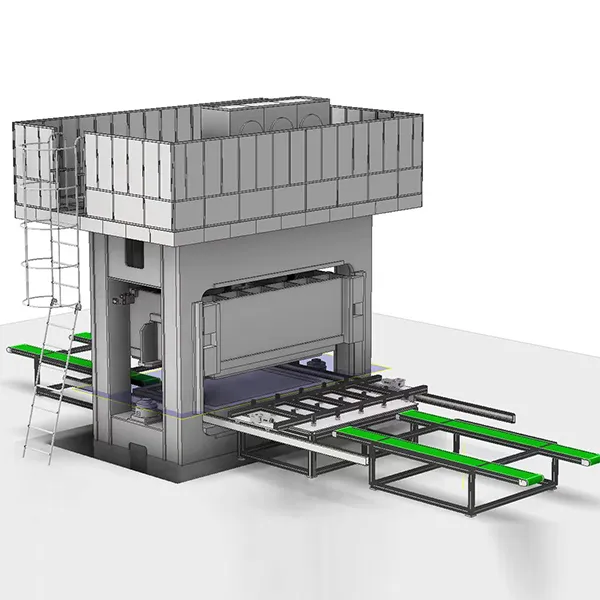

- H-Frame Hydraulic Press (Straight Side)

This press is ideal for manufacturing components such as housings, arc-extinguishing systems, and nozzles in electrical circuit breakers. It’s also suited for small SMC and BMC products, as well as compact carbon fiber parts, including components for drones.

| Model | | | | | | |

| Capacity (kN) | 1000 | 2000 | 3150 | 5000 | 6300 | 8000 |

| Mould opening force (kN) | 240 | 400 | 630 | 1000 | 1250 | 1600 |

| Table size (max. daylight /ram stroke) (mm) | 630×630 (900/600) | 900×900 (1100/710) | 1260×1260 (1250/800) | 1400×1400 (1300/900) | 1600×1600 (1600/1200) | 2000×1600 (2000/1500) |

| / | 1100×1100 (1100/710) | 1400×1400 (1250/800) | 1600×1600 (1600/1100) | 2400×1600 (2000/1500) | 2600×1800 (2500/2000) | |

| Closing speed (mm/s) | 120 | 120 | 120 | 150 | 150 | 150 |

| Pre-press speed (mm/s) | 6.4-16 | 5-22 | 5-18 | 5-18 | 5-18 | 5-18 |

| Pressing speed (mm/s) | 2-5 | 0.5-8 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

| Opening speed (mm/s) | 8-20 | 2-32 | 2-25 | 1-25 | 1-25 | 1-25 |

| Return speed (mm/s) | 65 | 95 | 95 | 95 | 100 | 100 |

| Power (kW) | 6.25 | 19.25 | 22.75 | 41.75 | 48.75 | 60.75 |

Please note: The above specifications are not final and can be adjusted according to your actual requirements. Any changes will be based on the parameters confirmed at the time of delivery.

This type of hydraulic press is designed for large-area fiber-reinforced composite products, including glass fiber and carbon fiber applications. It supports various molding technologies such as SMC, BMC, PCM, PHC, GMT, RTM, LFT-D, WCM, and HP-RTM. Typical products include integrated bathroom units, energy storage battery boxes, high-speed train interior parts, and automotive and aerospace components.

| Model | | | | | | |

| Capacity (kN) | 3150 | 5000 | 6300 | 8000 | 10000 | 12500 |

| Mould opening force (kN) | 800 | 1250 | 1500 | 2000 | 2500 | 3150 |

| Table size (max. daylight/ram stroke) (mm) | 1800×1400 (1600/1100) | 1800×1400 (1600/1100) | 1800×1400 (1600/1100) | 1800×1400 (1600/1100) | 2200×1600 (2000/1500) | 2200×1500 (2000/1500) |

| / | 2200×1600 (2000/1500) | 2200×1600 (2000/1500) | 2200×1600 (2000/1500) | 2600×1800 (2500/2000) | 2600×1800 (2500/2000) | |

| Closing speed (mm/s) | 150 | 250 | 300 | 300 | 300 | 300 |

| Pre-press speed (mm/s) | 5-20 | 5-25 | 5-25 | 5-25 | 5-25 | 5-25 |

| Pressing speed (mm/s) | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 | 0.5-5 |

| Opening speed (mm/s) | 2-20 | 1-20 | 1-20 | 0.5-20 | 0.5-20 | 0.5-20 |

| Return speed (mm/s) | 120 | 200 | 200 | 200 | 200 | 200 |

| Power (kW) | 26 | 51.5 | 59.5 | 74.5 | 92.5 | 116 |

Please note: The above specifications are not final and can be adjusted according to your specific requirements. Any changes will be based on the parameters confirmed at the time of delivery.

- Main Spindle Equipped with Hilead’s Proprietary HLA4V Axial Piston Pump Offers excellent resistance to contamination, high pressure capability, low noise, strong self-priming ability, stable performance under alternating loads, ability to handle radial pressure, multiple displacement control options, and a long service life.

- Innovative Frame and Cylinder Arrangement Utilizes a newly developed integrated plate frame structure from German technology, welded with premium materials. The frame has a rigidity ratio of 1/8000 and assembly precision improved by two levels. It also reduces damage caused by using small molds on large-table presses.

- Outstanding Low-Speed Stability While conventional composite presses rely on valve control systems, Hilead composite presses use pump control systems, achieving a minimum stable speed of 0.1 mm/s with virtually no energy loss.

- Oil-Free Lubrication Guide Rails Unlike the global standard of using oil lubrication, Hilead composite presses feature oil-free lubrication guide rails that protect the environment, prevent dust adhesion, and reduce wear.

- No Cooling System Required Most composite presses globally require large cooling systems. Hilead’s design eliminates this need, saving significant energy and water while avoiding equipment damage from leaks.

- Low-Noise Configuration By using low-noise motor and pump assemblies along with noise reduction measures, Hilead’s composite presses operate 6dBA quieter than conventional models.

- Energy Storage Feature During pressure holding, material placement, and part removal phases, the press stores pump energy and releases it during operation, reducing total motor power requirements by up to 50%.